[ad_1]

It replaces a polymer transistor, printed on film and wrapped around the tube, which fell apart when tested as part of an artificial pancreas – a catheter intended to detect blood sugar levels and transmit the information to a wearable insulin pump for diabetics.

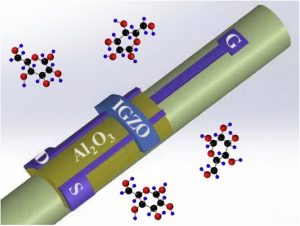

Key to the device is using an oxide semiconductor – amorphous InGaZnO (a-IGZO) – and contact printing the FET rather than using optical lithography.

“It takes advantage of an elastomeric stamp’s ability to conform to curved substrates with minimal distortion of the printed pattern,” said researcher Greg Herman. “The adhesion of the film deposition is very good. For it to come off, you’d essentially have to take a file to it. It’s much more rugged than what we had before, and the electronic performance is excellent – it’s the same as when fabricated on a flat surface using non-printing methods.”

Aluminium oxide is used as an insulator in the transistor, with indium tin oxide electrodes and glucose oxidase to functionalise the back-channel to glucose.

Because the transistor is transparent “you could start integrating optical fibres that have a-IGZO-FET sensors on them,” said Herman. “Some types of sensing need an optical response for detection, so if we can integrate an optical response with an electronic signal, we can expand the detection being done.” Plus, such fets could be combined with electro-physical imaging device, neural imaging devices and endoscopes.

According to ‘Transparent In-Ga-Zn-O field effect glucose sensors fabricated directly on highly curved substrates‘, published in Science Direct, the transistor on/off drain current ratio is around 1.3×106, combined with >7.4cm2/Vs average electron mobility and ~10−10 gate leakage. The glucose limit of detection is 170μM.

[ad_2]

Source link