[ad_1]

The demonstration is based on a 1/1.8’’ format, 1.3Mpixel CMOS image sensor.

“The standard sensor structure consists of a 7.74 x 8.12 mm silicon die glued on a ceramic package,” said Leti. “Electrical connections are wire bonded from the die to the package surface and, then, to the interconnection board. A glass cover is placed on top for mechanical protection.”

Instead, the lab ground the sensor thinner until it was less than 100µm thick, and therefore flexible, and then glued it to a concave curved (radius = 65mm) substrate. Wire bonding was using a modified process that does not damage the thinned die.

Instead, the lab ground the sensor thinner until it was less than 100µm thick, and therefore flexible, and then glued it to a concave curved (radius = 65mm) substrate. Wire bonding was using a modified process that does not damage the thinned die.

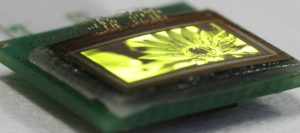

According to Leti, it will work with CMOS imagers, CCD imagers, infra-red sensors and microdisplay (convex OLED pictured)

Curved opto-electronics systems improves performance, while size, complexity and cost are reduced,” said Leti’s Bertrand Chambion. “Curved sensor technology is an approach for imaging applications such as photography, computer vision and surveillance.”

Chambion is an author of the paper ‘Curved sensors for compact high-resolution wide field designs: Prototype demonstration and optical characterization’, presented at Photonics West, in collaboration with Laboratoire d’Astrophysique de Marseille. Dubbed Pixcurve, the technology is also on show at Leti’s booth (431, Moscone Center).

Photo, the Pixcurve prototype and a commercial reference design.

[ad_2]

Source link