[ad_1]

It offers strength at temperatures between 1,400 and 1,600°C.

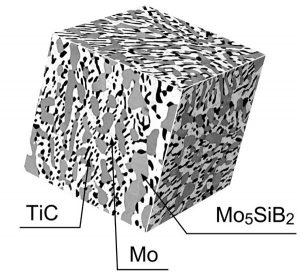

“Our experiments show that the MoSiBTiC alloy is extremely strong compared with cutting-edge nickel-based single crystal super-alloys, which are commonly used in hot sections of heat engines such as the jet engines of aircraft and gas turbines for electric power generation,” said engineer Professor Kyosuke Yoshimi.

Hot toughness demonstration: An MoSiBTiC tool welds Inconel 600 sheets by friction stirring.

Hot toughness demonstration: An MoSiBTiC tool welds Inconel 600 sheets by friction stirring.

More microstructural analysis is needed to fully understand the alloy’s mechanics and its ability to recover from exposure to high stresses, said the University.

And poor resistance to corrosion with air and moisture are suspected.

“Our ultimate goal is to invent a novel ultra-high temperature material superior to nickel-based superalloys and replace high-pressure turbine blades made of nickel-based superalloys with new turbine blades of our ultra-high temperature material,” said Yoshimi. “To go there, as the next step, the oxidation resistance of the MoSiBTiC must be improved by alloy design without deteriorating its excellent mechanical properties. But it is really challenging.”

For more, there is a paper here.

Images from Kyosuke Yoshimi

[ad_2]

Source link