[ad_1]

As vehicles become more sophisticated and automakers add more safety functions across their product ranges, it is now common to see entry-level models with features that were not even available on high-end versions a few years ago.

As advanced driver assistance system (ADAS) technology gains greater traction, we move ever closer to fully autonomous vehicles. Vehicle technology grows in complexity as additional functionality is integrated, architectures are reinvented and increased connectivity is mandated.

The introduction of emerging technologies is a challenge for design engineers and also impacts heavily on available test resources. Therefore, organisations supplying the automotive sector must use more flexible and innovative test equipment management strategies to keep pace with these dynamics and deliver project goals.

Safety increases

With studies showing that human drivers cause over 90% of accidents, the automotive industry sees fully autonomous vehicles as a path to drastically improving road safety.

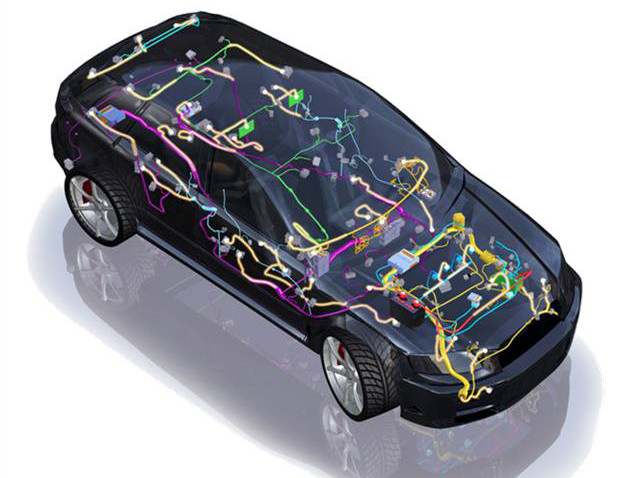

This journey is well underway, as more electronic features and functionality have been added. In fact, according to analyst firm Statista, the electronics content in an average car is now around one-third of its total cost, and this is predicted to grow to nearly half over the course of the next decade.

Initially, these enhancements took the form of separate modules, although now the trend is moving towards integrated ‘whole vehicle’ systems. Road safety will increase as more of the responsibility for decision-making moves from the human driver to the vehicle itself.

Automotive innovation will impact automotive testing

At a high level, the route to autonomous vehicles has been mapped out by organisations such as the Society of Automotive Engineers (SAE), but overcoming technical challenges will lead to unexpected directions being taken as the industry solves the challenges associated with new technology. As new technologies emerge, good management of testing needs is critical.

This may mean a reconfiguration of facilities, the upgrading equipment, or perhaps adding different types of instruments.

See also: Osram reveals future of LED automotive headlights

The accelerated innovation and lack of certainty over future technological solutions will drive an unprecedented need for suppliers and automotive test departments to react more quickly and broaden their testing capabilities. Rapid change means equipment will need to be replaced or upgraded more frequently, leading to equipment planning challenges and increased pressure on budgets.

Future testing will need to cover a wide range of technologies (including power management and control, high data-rate communication buses, wireless connectivity and sensing technologies) that will be implemented in modern vehicles. Additionally, as electrification moves further through the vehicle, more areas will become subject to test.

Powertrain

Whether in relation to conventional combustion engine cars, electric vehicles (EVs) or hybrid electric vehicles (HEVs), managing the efficient use of power reserves is becoming a key competitive advantage for automobile manufacturers.

The complex vehicle power systems found in next-generation vehicles will include DC-DC converters that supply different subsystems, as well as mechanisms for recovering kinetic energy from braking, ensuring that all available energy is directed towards extending the distance that the vehicle can travel before it needs to be recharged.

Through the use of sophisticated test instrumentation, more effective on-board power architectures can be constructed. Such tools are set to prove themselves invaluable in the testing of EV charging points as they start to be rolled out in greater numbers.

Internal communication

As vehicles move towards full autonomy, no longer can the electronic systems be a collection of disparate functional modules, as they have been in the past.

In order to provide the intelligence and perception required to approach human awareness, each of these functions has to combine into a single ultra-intelligent system. As many of the functions involved are safety-critical (such as ADAS obstacle detection), ultra-low latency within the system will be called for.

As a consequence, in-vehicle networking infrastructure is an increasingly important part of automobile design – with longstanding automotive buses such as CAN FD, LIN, FlexRay and MOST being augmented (or even supplanted) by other technologies, like Ethernet. High-speed buses will in turn need high-speed test capability.

The wireless aspect

Until recently, the communication functionality within vehicles was limited to the infotainment and satellite navigation systems. However, major transformations are now taking place – with the prospect of vehicles becoming connected to a greater breadth of communication nodes in the outside world. By transferring data to/from the infrastructure of smart cities, information can be imparted about vacant parking spaces or delays on a proposed route due to accidents or traffic jams.

This connectivity will also enable municipal authorities to monitor traffic flow and make adjustments to minimise congestion or pollution at peak times.

In addition to this vehicle-to-infrastructure (V2I) communication, in the future vehicles will also be able to communicate with each other via vehicle-to-vehicle (V2V) communication.

This will enable one vehicle to broadcast its intention to leave a road lane or arrive at an intersection, thereby significantly reducing the risk of collision. Likewise, details of traffic issues (such as an unexpected obstacle ahead) will be passed between vehicles to make them aware of these in advance.

Modern vehicles are already enabling travellers to connect via their smart devices, giving them access to applications that can make journeys easier and smoother (especially for younger passengers).

The ongoing proliferation of communications within vehicles will lead to multiple protocols (such as WLAN, Bluetooth and NFC) being implemented in the vehicle itself, with mobile protocols (such as LTE and LTE Advanced) being used for communications with other vehicles and the local environment.

Ensuring that hardware complies with the various communications standards involved will require access to an expansive range of test equipment.

EMC concerns

As already stated, the amount of electronics in modern vehicles continues to rise.

The average car today can easily comprise 70 to 90 electronic control units (ECUs). This brings two particular challenges with regard to electro-magnetic compatibility (EMC). Instrumentation is needed to monitor the amount of radiated energy created by the vehicle and also the susceptibility of sensitive constituent electronics inside the vehicle to externally generated EMC radiation.

Sensing technologies

As vehicles need to be more aware of the environment in which they are situated, the role that sensor devices play becomes increasingly vital – with comprehensive testing and verification being required.

GHz-band radar is a key development for vehicles, and is also used in infrastructure applications for position sensing and object detection. Likewise higher-resolution image sensors will need to be incorporated, so the HD object recognition systems can be employed by vehicles’ ADAS functions.

In time, LiDAR-based imaging will become commonplace. This will push the performance envelope in terms of data transmission – both in terms of the capacity and the latency that has to be supported.

Safety on our roads

The core objective of migration to automated vehicles is to increase driver/passenger/pedestrian safety. Through ADAS it is possible to detect objects, such as other vehicles, cyclists or pedestrians, thereby allowing them to be avoided without the need for driver intervention.

To ensure the operational integrity of the ADAS hardware employed by vehicles as the degree of complexity increases, thorough testing will be required. In many cases this will need to meet ASIL functional safety specifications.

Re-thinking the approach to testing

Accelerating development cycles and continually advancing technologies are putting a significant burden on test departments and their allocated budgets.

The traditional approach of simply buying all necessary test equipment is unlikely to be an option for most companies, other than a select few with very deep pockets.

The breadth of equipment needed for complex, multi-site projects can rarely be supported via a single sourcing model, and forward-thinking test supply companies must therefore offer multiple options to manage test equipment through the entire lifespan of a project.

Microlease has been at the forefront of the test business for over four decades. It is able to provide in-depth advice and consultancy to help users make decisions on how to approach complex test scenarios. As a result I believe it can significantly reduce the cost of testing and provide engineers working on projects for the automotive industry with the ability to modify their equipment base and individual unit specifications as needed.

Flexibility to adapt, access to the latest equipment and a wide range of items available from stock are some of the immediate benefits of working with a specialist like Microlease – which has the necessary size, scale and experience in this area. The capacity to deploy equipment on a pay-per-use model, for a few days, over a few months, leased for the longer term or sourced on a rent-to-buy basis means access to the right equipment when it is needed.

As project requirements change, equipment can be returned, upgraded or even traded in as necessary. This flexibility ensures that project cash flow is maximised and overall costs (in terms of both capital and operational expenditure) are kept to a minimum.

Going beyond equipment supply, Microlease also offers what I consider a comprehensive asset management and tracking service. This can be used to keep data on the location of each instrument, manage its calibration and servicing, and provide utilisation information – enabling better-informed decision making on when to exchange or dispose of a particular item.

Changing dynamics

The changing dynamics within the automotive sector are placing strain on all facets of the industry that supports it. Test departments must innovate to manage effectively and be more flexible, yet still deliver on stringent budgets.

While all this may seem daunting, by partnering with a recognised test sourcing specialist, automotive test departments and the supplier eco-system around them can make the necessary transformations and become more agile.

Those prepared to take a different approach to equipment sourcing and management will be best placed to achieve the breadth and flexibility needed.

Peter Spillman, Global Inventory & Procurement Director at Microlease

[ad_2]

Source link