[ad_1]

“We have venture capital firms already investing in this round that have been supporting us for a number of years as they believe in our novel technology,” says CEO Josep Montanya i Silvestre (pictured) “I think we are one of the first high technology companies to also offer the opportunity for people to easily invest using the simple process of Crowdcube. We already have 135 investors and raised £131,500 on Crowdcube, which is a 32% of the way to our target.”

Investing via Crowdcube can be done via a credit card payment or PayPal and only becomes effective once 90% of the target figure of £400,000 has been reached at the end of the crowd funding campaign.

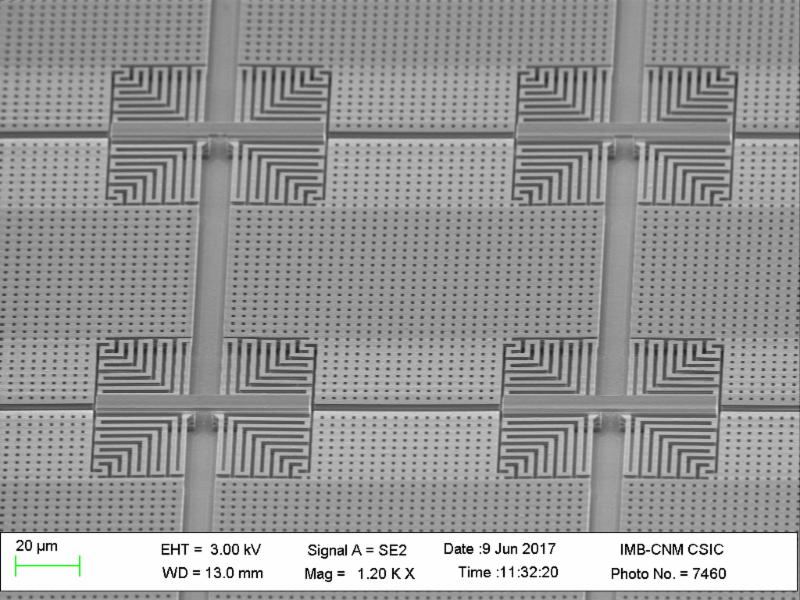

Founded in 2014, Nanusens is pioneering the development of nano-scale sensors that overcome a major problem of MEMS inertial sensors – stiction – by two orders of magnitude by reducing the sensor size by an order of magnitude into the nano-realm. Nanusens is VC funded by Inveready (www.inveready.com/venture-capital/), Caixa Capital Risc (www.caixacapitalrisc.es/en/) and Dieco Capital (www.dieco-capital.com).

Until now, sensors had to come off the standard CMOS production line to have the MEMS created on them using different processes. Nanusens multi-patent pending technology enables it to create nano-sensors using a standard CMOS processes within the same production flow as the rest of the chip production. This innovative approach dramatically reduces the size and cost of the sensors along with up to 85% reduction in the time to market.

“Our first silicon nano-sensor samples from GLOBALFOUNDRIES exceeded our expectations,” explained Montanyà, “with a sensitivity that is an order of magnitude above what is needed for a motion sensor in most applications. The mechanical operation of the nano-sensor design was the tricky part to get right, as that is where the innovation happens. That works perfectly and the design is fixed. Everything from now onwards just involves standard CMOS processes. Partnering with GLOBALFOUNDRIES will ensure good yields and that we will be able to rapidly ramp up production as sales take off. We have a disruptive technology solution that will revolutionise the sensor market and meet the ever-increasing demand for low cost sensors in smartphones, wearable technology and IoT devices that has already made sensors a multi-billion dollar industry.”

Nanusens has the supply chain fully defined, having partnered with trusted providers, like JCAP, member of JCET, the largest assembly group in China. The first product is planned to be ready by September. Upon finishing the electronic part and doing final qualification, sales will start. Nanusens is already in conversations with potential customers in China with whom the final specifications have been defined.

The Inter Metal Dielectric (IMD) is etched away through the pad openings in the passivation layer using vapour HF (vHF) to create the nano-sensor structures. The holes are then sealed and the chip packaged as necessary. As only a standard CMOS process with minimal post-processing is used, and the sensors can be directly integrated with active circuitry as required, the sensors can potentially have high yields similar to CMOS devices.

[ad_2]

Source link