[ad_1]

This process is a good way to make parts and prototypes that can be handled roughly.

Surface finish and mechanical precision is not as good as some of the precision processes, but post-printing processes like polishing and dying can make a big difference to appearance.

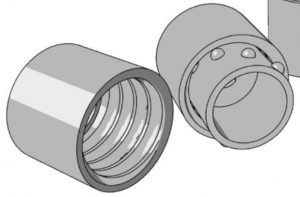

The guide is here, and I recommend having a look at the novel way suggested to make a screw thread that is not over-frictioned by the somewhat rough as-printed surface (see diagram).

Actually, I recommend reading it even if you are not printing anything – there is a lot of neat stuff in there.

For example, would you believe, good way to get the worst of the un-fused printing powder out of large hollow voids inside a print is…

- Before printing: design a floating chain running through the hollow voids

- After printing, pull the chain out – which will drag lots of powder with it

BTW, the prints are also porous – see here for sealing suggestions (one of which is in the guide above).

[ad_2]

Source link