[ad_1]

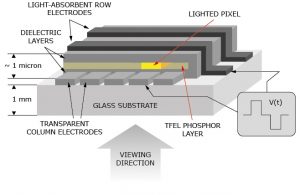

Pictured is the Tasel-branded ELT15S technology demonstrator.

“Tasel displays combine the rugged and reliable build of thin-film electroluminescence with the unique freedom of designing a completely transparent display,” said the firm. “It is ideal for consumer electronics, architectural use and other fields where viewing experience and product aesthetics is of paramount importance.”

The company is an atomic layer deposition specialist, whose other businesses include encapsulating flexible electronics, protecting OLEDs, solar cell surface passivation, x-ray machine moisture barriers and anti-tarnish treatment – for jewellery, RFID tags and optical components, for example.

“If you coated a full-size football field with Beneq’s nCLEAR moisture barrier, which is more commonly used for OLED encapsulation, less than a drop of water would infiltrate the whole surface in a day. That makes the coating a billion times better a moisture barrier than the typical alternatives,” said the firm.

The firm also makes non-see-through matrix displays.

The firm also makes non-see-through matrix displays.

Response time is said to be under 1 ms regardless of temperature.

“Over the last 30 years, TFEL technology has proven its excellence in applications ranging from monitor and control instruments in deep-sea vessels to operational systems in orbital spacecraft,” said Beneq. “Besides these extremes, TFEL displays have found their way into countless other applications, where uncompromised reliability and accuracy are required.”

[ad_2]

Source link