[ad_1]

The idea – for greater flexibility – is to be able to adjust the mechanical template at the heart of a design to a wider variety of shapes determined by user choice. The work has been done in collaboration with Adobe Research.

Thanks to Stevie B – our esteemed technology editor – for flagging this one. It’s via Eurekalert.org, which says:

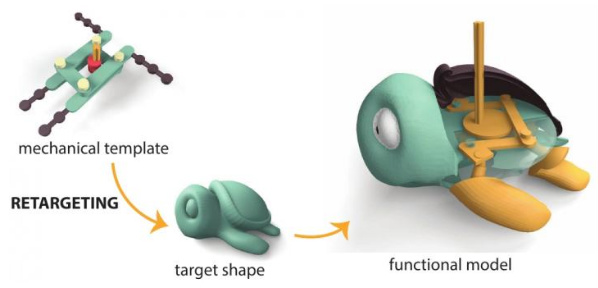

Common toys such as steerable cars or waving wind-up figures are available as 3D-printable models, which also contain their mechanical components. However, these mechanical structures are optimized to fit exactly one particular shape of the toy.

If designers want to reuse such a mechanism with different shapes, the necessary manual adjustments to the individual components are often unmanageable for non-experts, in addition to being extremely tedious.

The algorithm at the heart of the work will be presented by the PhD student Ran Zhang at the SIGGRAPH conference, which takes place in Los Angeles in July.

The image above represents the mechanisms for a waving wind-up toy to be adjusted to fit the shape of a turtle.

“Given a car model, there is usually one kind of mechanism that provides the functionality and, at the same time, thousands of different shapes that the car can have,” says co-author of the paper, Thomas Auzinger. “Our code bridges this gap and makes it possible to reuse the mechanism across all shapes.”

Mechanical templates

Possible uses? Apparently, different mechanical templates could cover wind-up toys, periodic motions of hand models, motorised remote control cars and even vehicles with moveable rotors, such as helicopters.

For each application, the design can be adjusted to produce a variety of variations, in terms of shape, while preserving the intrinsic functionality.

Image: IST Austria

[ad_2]

Source link