[ad_1]

The particular platinum-gold alloy is said to be 100x more durable than high-strength steel, making it the first alloy, or combination of metals, in the same class as diamond and sapphire, nature’s most wear-resistant materials, according to the lab.

“We showed there’s a fundamental change you can make to some alloys that will impart this tremendous increase in performance over a broad range of real, practical metals,” said Sandia materials scientist Nic Argibay.

It is not the combination of 90% platinum with 10% gold that is new, it is the engineering that goes with it that results in stable nano-scale grains.

The Sandia team, including Argibay, Michael Chandross and John Curry, proposed a new theory that says wear is related to how metals react to heat, not their hardness – a theory that sprang from simulations that calculated how individual atoms were affecting the large-scale properties of a material – a connection that’s rarely obvious from observations alone, said Sandia.

“We’re getting down to fundamental atomic mechanisms and microstructure and tying all these things together to understand why you get good performance or why you get bad performance, and then engineering an alloy that gives you good performance,” Chandross said.

The team then hand-picked metals, proportions and a fabrication process that could prove their theory, then modelled them.

“Many traditional alloys were developed to increase the strength of a material by reducing grain size,” said Curry. “Even still, in the presence of extreme stresses and temperatures many alloys will coarsen or soften, especially under fatigue. We saw that with our platinum-gold alloy the mechanical and thermal stability is excellent, and we did not see much change to the microstructure over immensely long periods of cyclic stress during sliding.”

The alloy is silver-white like platinum, no harder than other platinum-gold alloys, but much better at resisting heat and a hundred times more wear resistant.

According to the abstract of ‘Achieving Ultralow Wear with Stable Nanocrystalline Metals‘, a paper in Advanced Materials: “This is the first instance of an all‐metallic material exhibiting a specific wear rate on the order of 10-9mm3/N/m, comparable to diamond‐like carbon (DLC) and sapphire. Remarkably, the wear rate of sapphire and silicon nitride probes used in wear experiments are either higher or comparable to that of the Pt–Au alloy, despite the substantially higher hardness of the ceramic probe materials.” – The full paper is available free.

A potential application is on switch, relay and connector contacts.

“These wear-resistant materials could potentially provide reliability benefits for a range of devices we have explored,” said Chris Nordquist, a Sandia engineer not involved in the study. “The opportunities for integration and improvement would be device-specific, but this material would provide another tool for addressing current reliability limitations of metal microelectronic components.”

Serendipity

According to Sandia, despite all the predictive calculation, there was a surprise: “One day, while measuring wear on their platinum-gold, an unexpected black film started forming on top. They recognized it: diamond-like carbon, one of the world’s best man-made coatings, slick as graphite and hard as diamond. Their creation was making its own lubricant.”

Diamond-like is not usually easy to make, usually involving vacuum processing.

“We believe the stability and inherent resistance to wear allows carbon-containing molecules from the environment to stick and degrade during sliding to ultimately form diamond-like carbon,” said Curry.

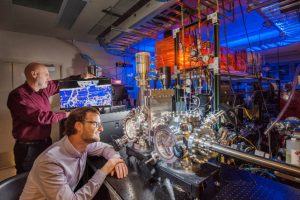

Photo: Sandia researchers Michael Chandross (left) and Nic Argibay with a computer simulation used to predict the wear resistance of their platinum-gold alloy, and an environmental tribometer used to demonstrate it.

[ad_2]

Source link