[ad_1]

Commercial printers designed for the job are expensive – costing over $10,000 – according to Carnegie Mellon University, where a team has developed an add-on for a standard desktop 3-D printer that converts it into a bio-printer for far less.

What’s more, they have open-sourced the design, released it for use, and made instructional videos.

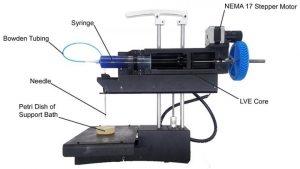

“What we’ve created,” said researcher Kira Pusch, “is a large volume syringe pump extruder that works with almost any open source FDM [fused deposition modelling] printer. This means that it’s an inexpensive and relatively easy adaptation for people who use 3-D printers.”

The printer implements the ‘free-form reversable embedding of suspended hydrogels’ (Fresh) technique, used in the laboratory of Cernegie researcher Adam Feinberg’s lab, which aims to produce open-source biomedical research that other researchers can expand upon – with the aim of encourage the development of life-saving biomedical technologies.

“Essentially, we’ve developed a bio-printer that you can build for under $500 [for the adaptor], that I would argue is at least on par with many that cost far more money,” said Feinberg. “It’s really about democratising technology and trying to get it into more people’s hands. The bio-printer allows us to print tissue scaffolds at the scale of an entire human heart, with high quality.”

The researchers recently published a paper in the journal HardwareX (Large volume syringe pump extruder for desktop 3D printers) that contains complete instructions for printing and installing the critical adaptor – a ‘large volume extruder’ (LVE) based around a standard 60cm3 syringe – on a PrintrBot Simple Metal printer.

[ad_2]

Source link