[ad_1]

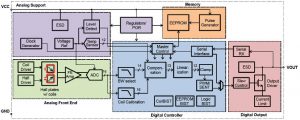

Called A1342, the monolithic BiCMOS IC has includes: a Hall sensing element, Hall temperature-compensating circuitry (both sensitivity and offset drift), a small-signal high-gain amplifier, dynamic offset cancellation, output linearisation circuitry, and the diagnostics.

And it is AEC-Q100 qualified for automotive use.

The 16bit ADC has user-selectable bandwidth for speed-sensitive applications and four-phase chopper stabilisation minimises temperature-induced offset drift.

Multi-segment temperature compensation is applied in the factory to give a flat baseline across operating temperature, then the customer can configure 1st and 2nd-order temperature sensitivity and 1st order temperature offset compensation.

“A key feature is its ability to produce a highly linear device output for non-linear input magnetic fields”, said Allegro. “To achieve this, the device features 16-segment customer-programmable linearisation, where a unique linearisation coefficient is applied to each segment. Coefficients are stored in a EEPROM look-up table.”

Lifetime drift, temperature drift and package-releated drift are all ±2.5% or lower, and depend if coil compensation is on or off. See page 8 of the data sheet for more details.

The device has two configurable options for the open-drain output: SENT (single edge nibble transmission) or PWM. In addition to SAEJ2716, there are two additional proprietary SENT options: SSENT and ASENT. Proprietary fast SENT provides increased data rates for high-bandwidth applications.

Both protocols enable bus configurations with up to four devices on one SENT line.

- SSENT provides sequential access to the sensors connected to the same line. It has a low overhead which maximises sensor bandwidth the single SENT line.

- ASENT provides random access to all the sensors on the common SENT line.

Both protocols allow individual sensors on the same line to enter diagnostic mode while the other sensors continue to respond to queries, “allowing for the highest diagnostic coverage while maintaining 100% availability of the sensor solution”, claimed Allegro. Output resolution is 12bit, but internally two more segments are implemented above and below the output range for linearisation without output clipping.

Signal fall time can be programmed to trade EMC against speed.

Diagnostics features are designed to ease system level ASIL compliance.

There is full signal and data path validation, including an internal magnetic coil to stimulate the Hall sensor and on-demand ‘logic built-in self test’ (LBIST) for the digital subsystem.

Fault detection includes: over-voltage, under-voltage, over-temperature, magnetic field out-of-range detection and broken wire detection for all three pins.

Not only does the EEPROM store coefficients and configuration, it includes a customer area for lot and date code information. Single error correction and double error detection (SECDED) is included.

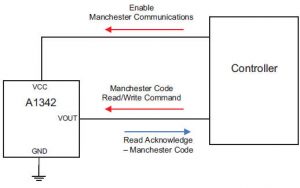

Not only does the output provide PWM or various SENT data formats, but it also acts as a bidirectional pin for programming. The Vcc pin becomes the other programming connection.

An integrated charge pump allows in-application programming without providing a high voltages.

A1342 is available in a through-hole, Pb-free 3 pin SIP package (UC suffix), with 100% matt-tin leadframe plating. The UC package includes the integrated capacitors for improved ESD performance and to enable PCB-less designs. They are 100nF from Vcc to ground and 1.5nF from output to ground.

The smaller plastic moulding hides no function, it is simply a lead bar to prevent damage during shipment.

[ad_2]

Source link