[ad_1]

Called WDBR-UL, they are thick-film-on-steel resistors, developed from the existing WDBR series, with creepage, clearances and power ratings assessed in accordance with the requirements of UL508, “easing the compliance burden for UL approved end-users,” said the TT. “For circuit designers who need to design UL approved systems containing power resistors in enclosed assemblies with heatsink-based thermal management, WDBR-UL provides a lower volume solution than encased wire-wound products.”

Applications are foreseen in motor drive inverters, dynamic braking, in-rush current limiting, snubbers, heaters in electronic assemblies, and providing over-voltage protection in wind turbines.

Construction detail

Nine values are available (12, 15, 20, 22, 25, 47, 50, 100, 150Ω) in five sizes options (170. 190. 240. 250 and 260W), according to the data sheet. These are continuous power ratings on a 0.53°C/W heatsink in 25°C, and rise to 660, 740, 850, 950 and 1,410W respectively with 5m/s forced air cooling.

Pulse ratings are between 1.5 and 7kW “and they are able to handle single overload power levels up to 13kW”, said TT.

Inductance is below 6μH.

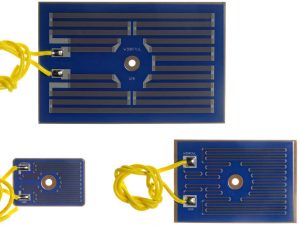

Construction comprises a high integrity dielectric layer applied to a machined stainless steel substrate which is then over-printed with thick-film conductor and resistor patterns.

This assembly is fired, and then protected with a high temperature glaze.

Terminations are either tinned pads (the parts are RoHS compliant) or flying leads.

[ad_2]

Source link