[ad_1]

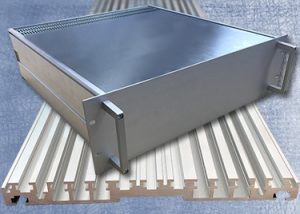

The external face of the sides have full length slots for fitting telescopic slides that ease withdrawal from a 19” rack for access.

The internal face of the sides has 12 channels into which tapped strips or individual M4 captive nuts can be slid to provide mounting points for housed components.

Ventilated or plain steel covers (with conductive finish) slide into dedicated slots, and conductive gaskets in these slots prevent movement and ensure conductivity. The hole pattern in the ventilated covers is intended to give efficient convection or forced cooling without compromising the EMC integrity.

Front and rear panels are 3mm anodised aluminium and are easily machined and drilled, said Vero. Locating holes for attaching these panels to the side extrusions are pre-drilled to break the surface anodising and maintain electrical conductivity. These fixing points are also used to attach front panel handles when required.

Cases come in standard depths of 240, 350 and 460mm, plus custom depths.

“It offers users good all-round access and easy assembly, and does away with the need for drilling when installing heavy components, chassis trays, brackets and electromechanical components. Top and base covers simply slide into place once the unit has been populated,” said the firm.

The case has been designed for applications such as audio, broadcast and instrumentation where EMC integrity could be an issue.

[ad_2]

Source link